About Us

MTEable specializes in the prototype, engineering development, and mass production of Promotional Toys & Gifts, which include PVC, TPE animal toys, dolls, Anime characters, action figures, and recycled plastic toys.

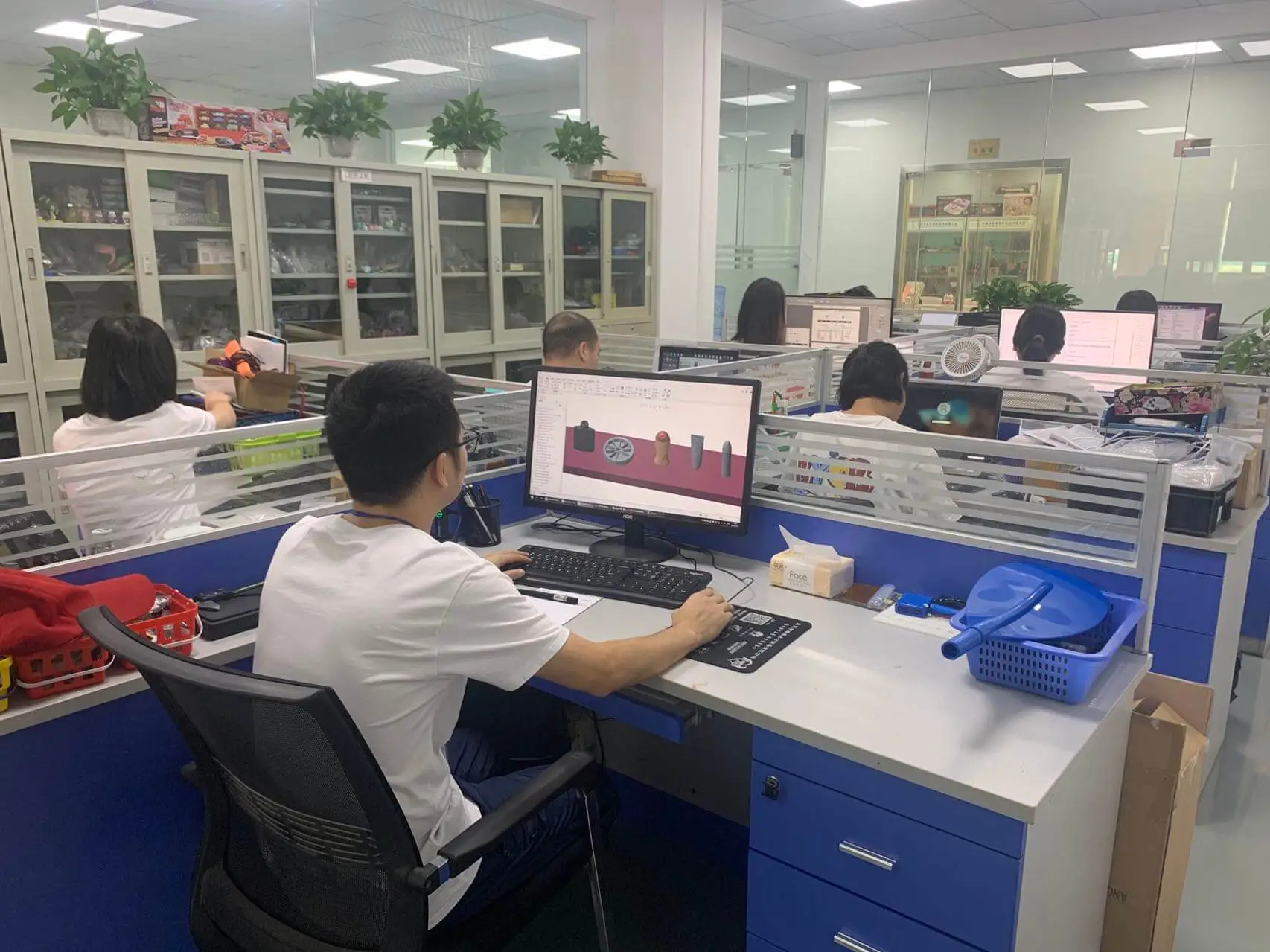

Real Production Plant

We have ISO-compliant production workshops and advanced production automation equipment. Welcome to visit our factory for guidance.

Manufacturing industry expertise

15 years of manufacturing experience with a Full-time team with unprecedented relationships in the factory sector, helping businesses find sustainable solutions.

Unparalleled support

Access to our innovative marketing materials and passionate in-house team, dedicated to help you promote your business increasing

Our Mission

Asist you achieve your target value is our motivation.

- Strong engineering capability

- Experienced in promotional toys/gift manufacturing

- Innovative knowledge with a good quality reputation

- Unique and effective Quality Control process

- Increase the construction of our own brand

- Increase the production ratio of retail sales

- Continue to maintain diversified markets to fully utilize capacity on an annual basis

What we have

Automatic production facilities

- Two plants, occupied area 7000 m2, Warehouse 3500 m2

- Injection machine 40 sets

- Automatic packaging machine 29 sets

- Semi-automatic assembly line 5 sets

- Automatic sealing machine 2 sets

- Semi-automatic Ultrasonic machine 12 sets

- Metal detect machine 3 sets

- Equipped with a complete set of physical testing equipment and laboratory

- Two automatic box sealers and several other machines.

- Strong engineering capability

- Experienced in promotional toys/gift manufacturing

- Innovative knowledge with a good quality reputation

- Unique and effective Quality Control process

Design For Manufacturability

Profoundly Understand the manufacturability of a design

- Reduce The Number Of Components And Features

- Consider Machining/Fabrication Standards

- Rely On Common Parts And Materials

- Avoid Tight Tolerances

- Design For Assembly

- Compliance/Testiing Questions to Ask When Designing

- Reduce The Overall Cost Of Manufacturing

- Improve the Production Process

- Increased Product Reliability and Stability

- Perfect product and engineering development process system

- Skilled and Stable product development and production team

- Centered and Pragmatic corporate culture cohesion

- Over 10 years experience in product design and tooling design.

- Over 10 years experience in production process and quality control.

GRS Production System

Recycling certification system suitable for plastic products industry

Why use recycled plastic

Recycled Plastic products with GRS(Global Recycling Standard- Accredited by Control Union Org) can reduce 72% of carbon footprint and produce zero New Fossil consumption.

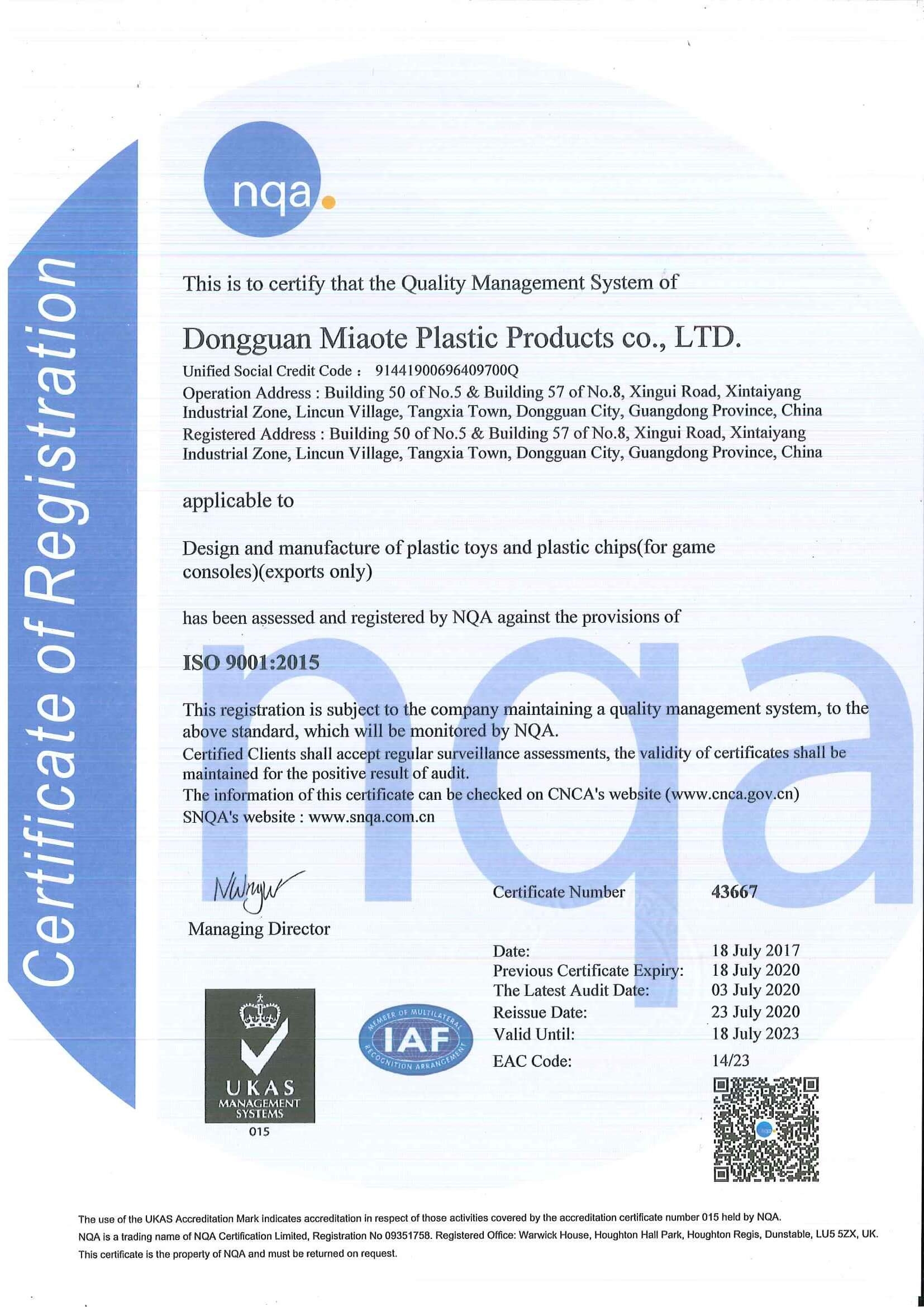

Certified System

The whole recycling system from waste recycling classification to purification and grain extraction is monitored and certified by ITS.

Dedicated Production Machine

All recycled materials are limited to special injection molding machines and are not mixed with machines using other raw materials.

Traceability of recycled products

The finished products from waste classification to recycled materials production are all in the traceability system, which is convenient for monitoring the use of recycled products in the market.

Certified Quality

Always Go Extra Mile and makes life easy and happy

MTEable production sites can adopt a very strict ethical code of conduct and to carry out, where necessary, any adjustments or corrective actions to our factories and production processes. Modern factories undergo periodic reviews and certification by certifying bodies such as TUV and ICQ (UL Group), SGS, and INTERTEK. Final random inspections are carried out before every shipment lot.CERTIFIED PRODUCTS

We consult with some of the most import certifying bodies and laboratories, such as ICQ/IISG, SGS, INTERTEK.

ON-SITE INSPECTIONS

We have internal lab and can evaluate basial physical safety test.

PRE-AUDIT OF THE FACTORIES

Personnel from qualified Supplier Access Team, carries out pre-audit inspections on the factories.